Electrical hazards

Dealing with power

Electrical hazards are common on live event job sites. An electrical hazard can be defined as:

- a dangerous condition where a worker could make electrical contact with energized equipment or a conductor, and from which the person may sustain an injury from shock or thermal burn, and/or,

- a dangerous condition where a worker could be exposed to an arc flash burn or arc blast injuries.

An electrical hazard is considered to be removed at the source only when de-energized and locked out; and reduced to acceptable levels when electrical insulation and approved enclosures are placed along the path between the worker and the electrical energy. Where PPE is relied upon for worker protection, the electrical hazard is considered to remain [IHSA].

ELECTRICAL HAZARDS AND LIVE EVENTS

Electrical hazards exist in live events when working on or near anything energized with power. The level of risk involved and the potential for harm increases when:

- energized cables are not installed correctly,

- cables are cut or damaged,

- connection points are sitting in liquid or are exposed to wet conditions, and

- when connection points have been tampered with.

IMPROPER INSTALLATION

Cables can sometimes get pulled, kicked, or stepped on resulting in a loose connection. For example, Socapex cables have a small tab/notch inside the socket to help line up the pins properly when connecting the male and female ends together. If these two ends aren’t lined up properly, we run the risk of energizing the outer shell of the connectors and potentially any other conductive material, such as steel or aluminum (e.g., a truss line or a steel pipe), that the cable may be in contact with.

CUT OR DAMAGED CABLES

Damaged cables pose a risk for harm or electric shock because there is a possibility of live exposed wires. These exposed wires could energize any metal objects they come in contact with. An example of this could be a scissor lift running over a cable connection that results in the cable being damaged or cut. Cuts in a cable jacket, no matter the size, should be addressed immediately and reported to your supervisor.

WET CONDITIONS

When working with live power in damp or wet environments, we run the risk of electrocution. Most water we come in contact with on site includes impurities, such as dissolved sodium, calcium, and magnesium salts, thus it is an excellent conductor of electricity.

OTHER CAUSES OF ELECTROCUTION

Some venues, predominantly industrial type buildings, can have live copper bars or bus bars in the ceiling or on a wall for the use of powering up overhead cranes or any other moving machinery. There is a high probability of electrocution when coming in contact with one of these bars, especially when operating an elevated lift platform. Any cable that has a missing or damaged ground pin can cause electrocution and should not be used.

TYPES OF POWER CABLES USED IN LIVE EVENTS

Socapex cables

Socapex cables have 6 circuits including a live, neutral and ground for each.

CamLock

CamLock is intended for distributing large amounts of power in the corporate or film industries wherever large generators are used.

Note: Crew Supply staff do not connect or disconnect Camlock cables at the source of power for safety reasons.

U-GROUND

U-Ground AC cables are the most commonly used cables and have the lowest risk of electrocution due to its longer ground pin.

L6-20

L6-20 Twistlock cables are used in lighting when 20 amps are needed to power a fixture.

7-Pin

Standard 7 pin multi cable are used to power and control motors.

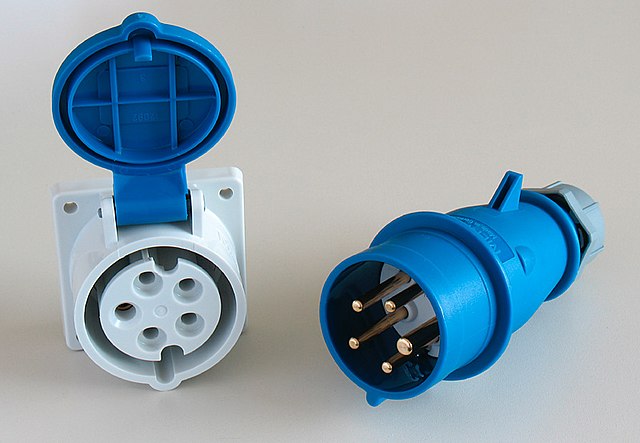

IEC C5 or Pin and Sleeve

SIEC C5 or Pin and Sleeve cables are used in high-traffic applications where moisture, debris, impacts, and accidental disconnections are a concern.

ACTION REQUIRED

Handling Power Hazards

Electrical hazards and dealing with power are part of the work we do in live events. The following provides best practices to lower the level of risk and potential for harm when exposed to electrical hazards.

- When installing cables, ensure all cables are plugged in securely and taped together if there is a risk of the cables coming apart.

- Visually inspect tools, equipment, cables, and cords before each use. Any cuts or damage to the cable’s jacket, shield or connectors, or any missing pins must be reported to your supervisor.

- Inspect the workspace and cable path for any pools of water before starting to run your cables. If there is any liquid or pooled water along the cable path then report the hazard to your supervisor.

- When working in an area where copper bus bars are present, give a wide berth and stay at least 10 meters away.

- On a dismantle, ensure that a cable is unplugged before your start coiling up the cable. If you are unsure if the cable is unplugged or don’t have access to the area the cable is plugged in to, then inform your supervisor and come back to it later once you know it is safe to coil.

- For lighting fixtures, ensure:

- Fixtures are secured with safety chains

- Barn doors and other accessories are attached to the fixtures with safety chains.

- Gels are slotted into the gel holders properly, so they don’t come out (ensure the clips are down)

- Plugs are properly twisted and locked into place.

As part of our Health and Safety program, it is important to remember that Crew Supply staff will not:

- Calculate electrical loads

- Carry out high amperage power tie-ins

- Flip the main circuit breaker to energize a distribution system

- Replace lamps in lighting fixtures, projectors etc.

- Be responsible for weather-proofing electrical connections (outdoors)

- Carry out work near energized overhead power lines

- Disconnect or deal with any cabling directly related to power distribution. For example, Crew Supply workers are not to unplug:

- feeder cable/camlock,

- cables from a power distro, and

- cables from a generator.

- Wrap cable that is still connected to a live power source.

Please refer to our Health and Safety Handbook – Section 14.15 Electrical/Lockout Hazards for more information.

FURTHER INFORMATION

Electrical Safety – Basic Information (Canadian Centre for Occupational Health and Safety – CCOHS)

Electrical shock: First aid (Mayo Clinic)

Electrical Safety Guideline for the Live Performance Industry in Ontario (Ministry of Labour, Training and Skills Development)

This Health and Safety Snapshot was brought to you by Cavan Sladen, Crew Chief and Certified JHSC Worker Representative at Crew Supply Inc. Cavan has extensive experience supervising large crews and is Crew Supply’s key person for workplace and safety inspections. He has a passion for health and safety and serves as Co-chair on Crew Supply’s Joint Health and Safety Committee.